Key Considerations for Modern Supply Chains

Plastic pallets play a critical role in warehouses and distribution networks around the world. While they may appear similar at a glance, not all pallets are engineered to perform the same way. Selecting the right pallet for your application can significantly impact efficiency, safety, and long‑term operating costs. Below are five essential factors to consider when evaluating distribution pallets.

1. Pallet Size

The most common footprint in North American distribution is the GMA‑standard 48″ x 40″ pallet, widely used in food manufacturing and grocery supply chains. Other popular sizes include:

- 30″ x 42″ — ideal for direct‑to‑store delivery

- 1200 mm x 1000 mm (EUR1) — a widely used European standard

Choosing the correct footprint ensures compatibility with your equipment, racking, and downstream partners.

2. Load Capacity

Load capacity refers to how much weight a pallet can safely support in different environments. It must meet or exceed the weight of your intended load. Capacity is typically measured in three ways:

Static Load Capacity

How much weight a pallet can support while stationary — for example, when stacked on a warehouse floor.

Dynamic Load Capacity

The maximum evenly distributed weight a pallet can handle while being lifted or moved by forklifts or pallet jacks.

Racking Load Capacity

The maximum distributed weight a pallet can support in a racking system. Performance varies depending on whether the rack is supported or unsupported.

Because racking systems differ widely, it’s always best to consult a knowledgeable supplier to ensure the pallet matches your facility’s requirements.

3. Pallet Durability

Durability is a major factor in both safety and cost. Pallets not designed for heavy loads can break, damaging products or creating hazards for employees. Material choice also matters:

- Structural foam pallets contain air pockets, making them more brittle and prone to cracking.

- High‑pressure injection molded pallets offer superior impact resistance and longer service life.

A durable pallet reduces downtime, product loss, and workplace injuries.

4. Cleanliness

Some industries — especially food processing and pharmaceuticals — require strict hygiene standards. Not all pallet materials are suitable for these environments.

Injection molded plastic pallets offer:

- Smooth, non‑porous surfaces

- Resistance to bacteria, pests, and moisture

- Easy wash‑down and sanitation

These characteristics make them ideal for cleanrooms and regulated facilities.

5. Overall Pallet Cost

The lowest upfront price doesn’t always translate to the lowest total cost. Cheaper pallets may lead to:

- Higher freight costs

- More frequent replacements

- Increased product damage

- Lower productivity

- Greater risk of employee injury

Investing in a higher‑quality pallet often results in a lower cost of ownership over time.

Benefits of Injection Molded Plastic Pallets for Distribution

Injection molded pallets are widely recognized for their strength, consistency, and long‑term value. They offer several advantages over other pallet types.

Durable & Strong

High‑pressure injection molded pallets are engineered for impact resistance and can often remain in service even after forklift tine strikes. They experience significantly less breakage than structural foam pallets, making them ideal for demanding distribution environments.

Safe & Hygienic

These pallets feature:

- Smooth, non‑porous surfaces

- Resistance to microbial growth and chemical contamination

- No splinters or sharp metal components

- Lightweight construction for safer manual handling

They can be washed and returned to service quickly, supporting high‑volume operations.

Sustainable

Plastic pallets have a long lifespan and can be fully recycled at end‑of‑life. Many models can also be manufactured using recycled material, helping organizations reduce waste and support sustainability initiatives.

Cost‑Effective

Injection molded pallets are lightweight and use less material, reducing freight costs from the very first shipment. While the initial investment may be higher, facilities typically see rapid ROI through:

- Reduced breakage

- Improved operational efficiency

- Lower product damage

- Longer service life

Plastic Pallet Options Available Through Ak‑West Inc.

Ak‑West Inc. supplies a wide range of high‑performance injection molded pallets designed to meet the needs of distribution, retail, and export applications. Options include:

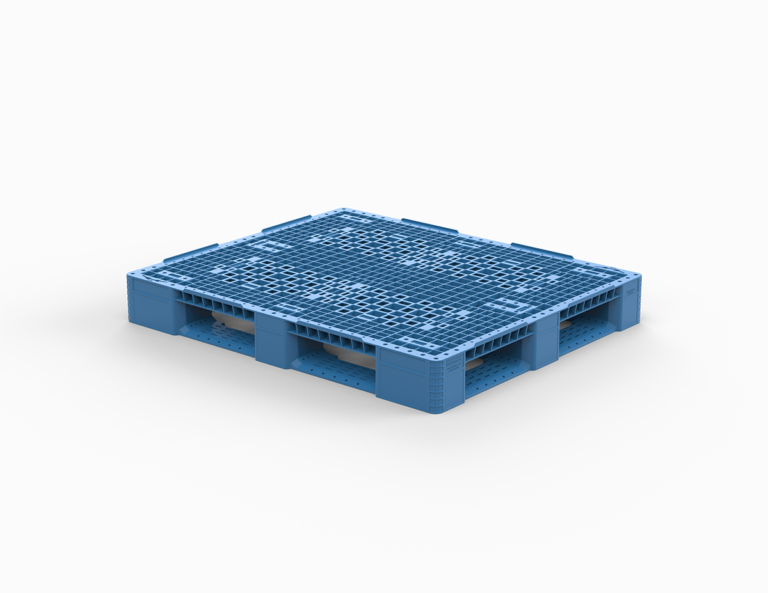

Nestable 48″ x 40″ Injection Molded Welded G2 Pallet

A two‑piece welded design with enhanced internal ribbing for exceptional strength, durability, and low tare weight — ideal for heavier loads.

Nestable 48″ x 40″ Injection Molded Pallet

A GMA‑footprint pallet designed for distribution, retail, and high‑end export applications.

Nestable 1200 mm x 1000 mm Injection Molded Pallet

A one‑piece pallet built around the EUR2 footprint, commonly used in international and retail environments.

Nestable 30″ x 42″ “Half” Pallet

Perfect for retail and direct‑store delivery. Its compact footprint fits through standard doorways, and ergonomic handles improve handling safety and efficiency.

All pallets supplied by Ak‑West Inc. are 100% recyclable and available in versions made with recycled material.

Your Partner for Distribution‑Ready Plastic Pallets

Ak‑West Inc. provides high‑quality plastic pallets designed to meet the performance demands of modern distribution. With a wide variety of options and industry expertise, we help customers identify the most effective pallet solution for their operational needs.